For decades, businesses have relied on a myriad of wired and wireless technologies to connect PCs, communication systems and corporate applications. While Wi-Fi has become ubiquitous in all types of enterprises, today’s industrial operations need more reliable connectivity to support the onslaught of automation, robotics and AI-driven systems.

It’s worth noting that a vast majority of manufacturing and logistics operations still use wired networks to connect existing equipment. But wires are quickly going the way of the dinosaur as factories, warehouses and other industrial facilities become more dynamic and require the flexibility and mobility of wireless.

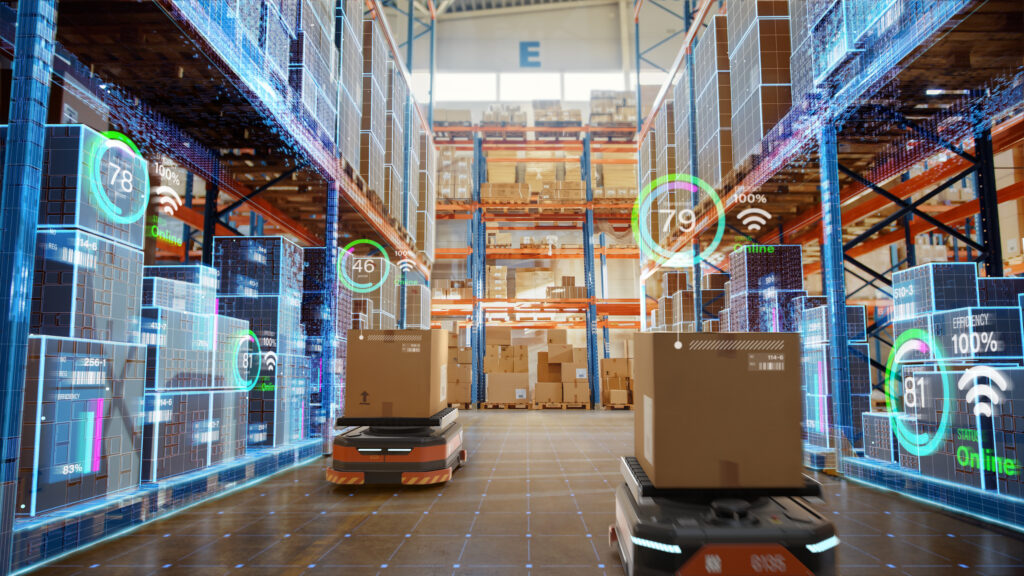

RELIABILITY MATTERS: Imagine a busy warehouse with autonomous forklifts on the move. They rely on uninterrupted wireless signals to get real-time instructions that optimize their route and avoid obstacles. At best, unexpected interference could impact robotic operations and create costly disruptions in productivity. At worst, poor wireless connections could turn these unmanned vehicles into a serious safety threat to workers and other equipment.

What’s wrong with Wi-Fi?

To be fair, Wi-Fi technology has evolved over the years with greater speed and capacity to handle more devices and more bandwidth-intensive tasks. Thanks to widespread availability and familiarity, Wi-Fi will continue to be a mainstay in most businesses, schools, and public venues. But the truth is that Wi-Fi wasn’t built for the demands of today’s industrial automation.

Wi-Fi is known as a “best effort” communication medium, which means that actual performance depends on many variables, including traffic load, environmental factors, and other devices sharing the airwaves. Operations managers are no strangers to the costly impact of Wi-Fi downtime on productivity – caused by insufficient network coverage, physical obstacles, outdated equipment, or all of the above.

The advent of 5G has made private cellular networks a more reliable and cost-effective option for industrial connectivity. Let’s explore some of the key differences that make Betacom 5GaaS a better choice: coverage, interference, and purpose-built design.

Coverage:

Most industrial facilities have an expansive footprint with a lot of steel and concrete. These environments are not very friendly to Wi-Fi signals that operate at lower output power, which means more access points are needed for adequate coverage and performance. More access points not only add cost and complexity, but requires more handoffs as robots and devices move from place to place. Wi-Fi roaming is notoriously problematic for applications that depend on low-latency connections, as devices are forced to disconnect from one access point before establishing a connection with the next.

By comparison, 5G access points can cover a 3-5x larger indoor area than a typical Wi-Fi access point and are better able to navigate around physical obstacles. This can greatly reduce the amount and cost of equipment needed in a large facility. And like other cellular technologies, private 5G is designed for seamless handoffs and more predictable performance as devices roam throughout a building.

Interference:

Wi-Fi uses a swath of unmanaged radio spectrum known as the Industrial, Scientific, and Medical (ISM) band. Those airwaves are shared by many types of wireless technologies and devices, including one-fourth of industrial equipment. The more devices sharing spectrum without any form of air traffic control, the more interference that can lead to poor performance and dropped connections. In addition to interference from other wireless devices, the harsh industrial environments we mentioned earlier can also cause multipath interference as signals reflect from metal racking and concrete surfaces.

Conversely, Betacom 5GaaS uses a part of the 5G spectrum that was set aside for business use – known as Citizens Broadband Radio Service (CBRS). Operating in the 3550-3700 MHz band, CBRS networks can support thousands of devices and the airwaves are strictly controlled to reduce interference from one another. Private CBRS networks are also designed to transmit at a lower power level to stay within a local area (like a warehouse or factory), which makes them virtually immune from interference from nearby networks.

Purpose-Built Design:

When building or augmenting your technology infrastructure, design matters. Private 5G networks are purpose-built to meet a customer’s needs. Whether blanketing an entire facility or providing low-latency connectivity for a specific area, the network can be optimized for the unique requirements of the use case and environment. Additionally, Betacom’s 5GaaS is backed by service level agreements (SLA) that guarantee the performance and reliability KPIs defined by the customer.

Although Wi-Fi networks have some level of flexibility in how they are deployed, DIY’ers can be stuck with out-of-the-box settings that are not tuned to their facility or the needs of their automation systems. And since there’s no performance guarantee, customers are usually forced to add expensive access points in places that need better coverage.

When it comes to wireless connectivity, there is no panacea for every environment. For the foreseeable future, both carpeted and industrial enterprises will continue to use a combination of technologies to support their business applications and try new things as they modernize and automate their operations. Fortunately, the private 5G market is emerging at the right time to fill the shortcomings and accelerate Industry 4.0 innovations.

For information about the other advantages of private 5G networks, check out GigaOM’s CXO Decision Brief.